surface grinding machine pdf

G5963 6 x 12 Surface Grinder w Stand Precision grinding perfect for the small tool room and metalworking enthusiast. Road surface marking is any kind of device or material that is used on a road surface in order to convey official information.

Hydraulic Surface Grinding Machine Banka Machine

I assumed that you already have a brief idea about Grinding Machine.

. Abrasive blast cleaning to achieve a surface profile using non-metallic abrasive media which is suitable to achieve a sharp and angular surface profile. 42 gives a guideline for the capability of different manufacturing processes in terms of achievable quality grade. A suitable grinding wheel may be selected for surface grinding operation.

With its quick retooling feature the SATURN double surface grinding machine from JUNKER is not only flexible but also an economical and reliable solution for precision production of diverse connecting rods. JUNKER developed a game changer for rotor shaft manufacturing. Stages of manufacturing processes are to be accordingly decided.

As my previous article of Grinding Machine I told grinding is an important operation in manufacturing industry to get a final product so for that we need to know about the grinding wheel and its properties so that we easily choose a right wheel for the right material. It involves grinding flat surfaces. Machine work fixture cutter arbor machined blanks and also the cutting parameters add some amount of errors to different gear elements.

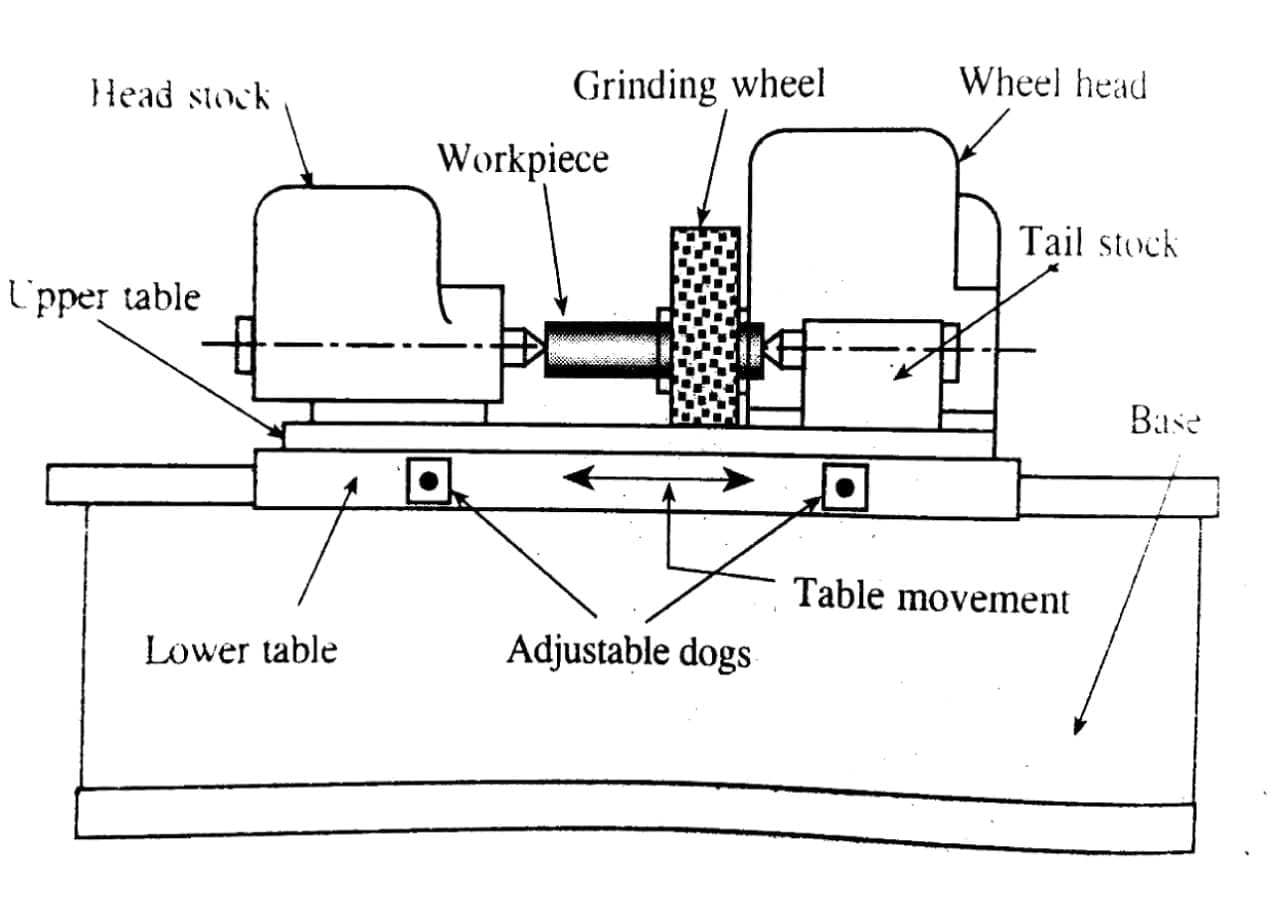

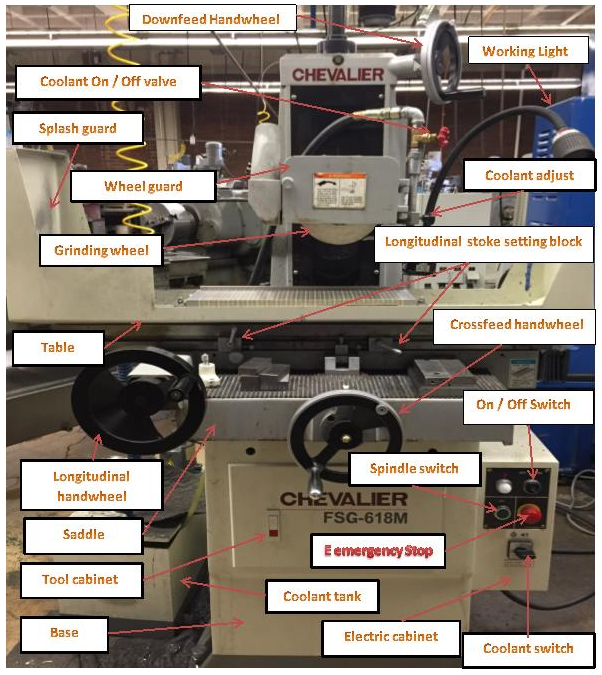

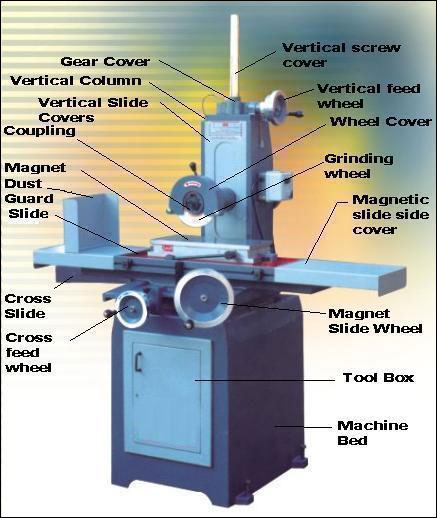

Machine tool - machine tool - Basic machine tools. Grinding operations are utilized by a table that moves on a horizontal plane and a grinding wheel that moves along a vertical axis. The grinding wheel is made to revolve with the spindle and is fed up and down.

All in one grinding machine - JUNKER developed new technologies that allow the complete grinding of. Aluminium The surface shall be hand or machine abraded with non-metallic abrasives or bonded fibre machine or hand abrasive pads to impart a scratch pattern to the surface. PDF Basics of Mechanical Enginnering- Notes - Introduction to machine and machine tools Find read and cite all the research you need on ResearchGate.

Grinding is used to finish workpieces that must show high surface quality eg low surface. They are commonly placed with road marking machines also referred to as road marking equipment or pavement marking equipmentThey can also be applied in other facilities used by vehicles to mark parking spaces or designate areas for other uses. Fritz Studer AG is a market and technology leader in universal external and internal cylindrical grinding as well as noncircular grinding.

Hundreds of varieties of metal machine tools ranging in size from small machines mounted on workbenches to huge production machines weighing several hundred tons are used in modern industry. The G5963 6 x 12 Surface Grinder allows you to resurface metallic workpieces to create high-tolerance flat surfaces. It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracy.

A grinding machine often shortened to grinder is one of power tools or machine tools used for grindingIt is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. Shaper Machine is a production machine in which the single point cutting tools are attached and the workpiece is fixed and while moving forward the tool cuts the workpiece and in return there is no cut on the workpiece and. Grinding Machine Operation.

The common grinding machine operation are surface cylindrical internal and centreless grinding. Grinding operation may be performed in a drilling machine to finish a hardened hole. Now let us discuss each one by one 1.

Here the workpiece is fitted with a magnetic chuck attached to a work table of the grinder. Shop primed steel Dry clean and approved. They retain the basic characteristics of their 19th- and early 20th-century ancestors and are still classed as one of the following.

Grinding can also be done correctly out of roundness of the hole. If you not learned yet. Non-magnetic are held by vices or.

Surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece.

14 Types Of Grinding Machines Working Diagram Pdf

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

14 Types Of Grinding Machines Working Diagram Pdf

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

Muhammad Musa Muslimmuhammad313 Profile Pinterest

Grinding Machine Parts And Functions Mechanical Walkins

Chapter 5 Surface Grinder Manufacturing Processes 4 5

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Surface Grinding Machine At Best Price In India

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

Manual Surface Grinder Wheel Head Moving Surface Grinders Manufacturer From Faridabad

Parts And Functions Of Grinding Machine Grinding Machine Grinding Machine Types

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

14 Types Of Grinding Machines Working Diagram Pdf

8 Types Of Grinding Machine Parts Working Principle Grinding Wheel Complete Details Engineering Learn